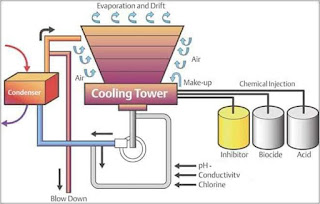

Cooling Towers is a part of the engineer's job, and it's where the engineer can find different problems.

When blowdown occurs, circulation water and treatment chemicals are also lost along with the solid waste, so it’s important to monitor this closely. If your cooling tower requires too much blowdown, it could be an indication that the water treatment system isn’t running as efficiently as it could be or feeding the cooling tower water pure enough for the process.

An effective cooling tower water treatment system will provide the right quality of water , the correct circulation chemistry , allowing it to run efficiently, avoiding problematic deposition, and maintaining a manageable amount of blowdown. This helps conserve the amount of any makeup water or chemicals needed and results in a higher-solid waste.

The Most Common Problem of Cooling Towers Operations is Loss of Water & Chemicals by Increasing the Cooling Towers Blowdown Rate. Since cooling towers remove heat by the process of evaporation, it’s no surprise that they, in turn, can use lots of water to make up the difference.

Depending on the quality of makeup water being added to the cooling tower and the operation efficiency of the unit, large amounts of solids can remain after evaporation occurs, causing an increased need to “blow down” or remove solid waste and dissolved solids buildup from the circulation water before it has a chance to scale or corrode equipment.

|

An effective cooling tower water treatment system will provide the right quality of water , the correct circulation chemistry , allowing it to run efficiently, avoiding problematic deposition, and maintaining a manageable amount of blowdown. This helps conserve the amount of any makeup water or chemicals needed and results in a higher-solid waste.

Some solutions to decreasing the amount of cooling tower blowdown might include:

- Improved feed water filtration

- Higher-quality side-stream filtration

- Increased cycle of concentration

- Maintaining better makeup water chemistry by removing scale forming and corrosion causing impurities.

- Change or closely manage the cooling tower feed chemistry program

PRODUCTION & OPERATIONS SUPERINTENDENT – QATAR

APPLY now Resumes@petro-staff.com in WORD

APPLY now Resumes@petro-staff.com in WORD

To operate the Operations South sector field in a safe and efficient manner ensuring all the activities are conducted with due regard to operational priorities, safety of the personnel and plant and environmental impact to ensure production of 115, 000 barrels of crude oil per day, 300,000 BBLS water injection and 150 mmscf of RAG is met.

This position is has Supervisory responsibilities of personnel working on the facility irrespective of their departmental reporting relationships.

Good interpersonal and managerial skills to analyze and solve problems onsite within his capacity. Should be able to handle emergencies as an on- site team leader.• Fifteen {(15) years broad process / production background, with at least five (5) years as supervisory level in oil and gas process operations.• Excellent communication skills in English Spoken and writing.

Education

B.Sc. in an Engineering discipline, preferably Chemical/Petroleum engineering.

B.Sc. in an Engineering discipline, preferably Chemical/Petroleum engineering.

JOB OPPORTUNITY FOR ENGINEERS & FOREMAN

Our client, a renowned Oil & Gas organization in UAE is looking for Engineers & Foreman’s.

Hiring below positions for Stacked Rigs reactivation & Major maintenance project.

Desired Candidate with minimum of 10 – 15 Years’ experience with drilling rigs equipment overhauling, operation & maintenance & commissioning of land rig components.

Mechanical Engineer – 10 Nos

Electrical Engineer – 10 Nos

Mechanical Foreman – 10 Nos

Electrical Foreman – 10 Nos

Candidate with relevant qualification such as Diploma / Degree in similar background i.e. Mechanical & Electrical may apply for the same.

Preferred candidates from Oil& Gas background with offshore experience in large maintenance projects.

Kindly email your updated resume to talent@sundusrecruitment.com with the below details:

Current Salary:

Expected Salary:

Notice Period:

Note: Kindly mention your job title in the Subject line of the Email.

We are not the responsable, we only share the opportonuties

A reactor was fitted with a bypass

(Figure 1 ), The remotely operated valves A, B, and C were interlocked so that C had to be open before A or B could be closed.

It was found that the valves leaked, so hand-operated isolation valves (a, b, and c) were installed in series with them (Figure 2).

After closing A and B, the operators were instructed to go outside and close the corresponding hand valves a and b. This destroyed the interlocking.

One day, an operator could not get A and B to close. He had forgotten to open C. He decided that A and B were faulty and closed a and b. Flow stopped, The tubes in the furnace were over- heated. One of them burst, with no lives loss

Lesson Learned

Any Plant Modifications even minor ones shoukd undergo only through the Plant MOC ( Management of Change ) Procedure Only and the human error should be taken in consideration when you do the MOC PHA, also Updating the SOP is part of MOC Implementation process ( Document Update ) and training of all concerned about the New Changes,

also the PSSR ( Pre Start Safety Review ) should be done prior the actual implementation of the MOC to address any human or process hazards

Subscribe to:

Comments (Atom)