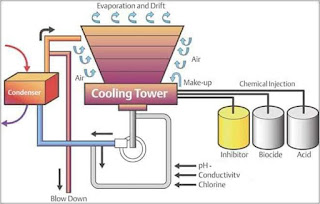

Cooling Towers is a part of the engineer's job, and it's where the engineer can find different problems.

When blowdown occurs, circulation water and treatment chemicals are also lost along with the solid waste, so it’s important to monitor this closely. If your cooling tower requires too much blowdown, it could be an indication that the water treatment system isn’t running as efficiently as it could be or feeding the cooling tower water pure enough for the process.

An effective cooling tower water treatment system will provide the right quality of water , the correct circulation chemistry , allowing it to run efficiently, avoiding problematic deposition, and maintaining a manageable amount of blowdown. This helps conserve the amount of any makeup water or chemicals needed and results in a higher-solid waste.

The Most Common Problem of Cooling Towers Operations is Loss of Water & Chemicals by Increasing the Cooling Towers Blowdown Rate. Since cooling towers remove heat by the process of evaporation, it’s no surprise that they, in turn, can use lots of water to make up the difference.

Depending on the quality of makeup water being added to the cooling tower and the operation efficiency of the unit, large amounts of solids can remain after evaporation occurs, causing an increased need to “blow down” or remove solid waste and dissolved solids buildup from the circulation water before it has a chance to scale or corrode equipment.

|

An effective cooling tower water treatment system will provide the right quality of water , the correct circulation chemistry , allowing it to run efficiently, avoiding problematic deposition, and maintaining a manageable amount of blowdown. This helps conserve the amount of any makeup water or chemicals needed and results in a higher-solid waste.

Some solutions to decreasing the amount of cooling tower blowdown might include:

- Improved feed water filtration

- Higher-quality side-stream filtration

- Increased cycle of concentration

- Maintaining better makeup water chemistry by removing scale forming and corrosion causing impurities.

- Change or closely manage the cooling tower feed chemistry program

Cooling Towers Problems And Solutions

Cooling Towers is a part of the engineer's job, and it's where the engineer can find different problems.

When blowdown occurs, circulation water and treatment chemicals are also lost along with the solid waste, so it’s important to monitor this closely. If your cooling tower requires too much blowdown, it could be an indication that the water treatment system isn’t running as efficiently as it could be or feeding the cooling tower water pure enough for the process.

An effective cooling tower water treatment system will provide the right quality of water , the correct circulation chemistry , allowing it to run efficiently, avoiding problematic deposition, and maintaining a manageable amount of blowdown. This helps conserve the amount of any makeup water or chemicals needed and results in a higher-solid waste.

The Most Common Problem of Cooling Towers Operations is Loss of Water & Chemicals by Increasing the Cooling Towers Blowdown Rate. Since cooling towers remove heat by the process of evaporation, it’s no surprise that they, in turn, can use lots of water to make up the difference.

Depending on the quality of makeup water being added to the cooling tower and the operation efficiency of the unit, large amounts of solids can remain after evaporation occurs, causing an increased need to “blow down” or remove solid waste and dissolved solids buildup from the circulation water before it has a chance to scale or corrode equipment.

|

An effective cooling tower water treatment system will provide the right quality of water , the correct circulation chemistry , allowing it to run efficiently, avoiding problematic deposition, and maintaining a manageable amount of blowdown. This helps conserve the amount of any makeup water or chemicals needed and results in a higher-solid waste.

Some solutions to decreasing the amount of cooling tower blowdown might include:

- Improved feed water filtration

- Higher-quality side-stream filtration

- Increased cycle of concentration

- Maintaining better makeup water chemistry by removing scale forming and corrosion causing impurities.

- Change or closely manage the cooling tower feed chemistry program

No comments:

Post a Comment